Механизированная штукатурка стен в Димитровграде: Современные технологии и преимущества

Механизированная штукатурка стен в Димитровграде – это инновационная технология в строительстве, которая значительно упрощает процесс отделки стен и улучшает качество конечного результата. В последние годы она приобретает всё большую популярность среди профессиональных строителей и домашних мастеров. В этой статье мы рассмотрим основные аспекты механизированной штукатурки, её преимущества, процесс выполнения и используемое оборудование.

1. What is mechanized plaster?

Mechanized plaster is a method of applying plaster mortar to walls using special machines and aggregates. Unlike traditional manual plastering, where the mortar is applied with a spatula and trowel, the mechanized method involves the use of plaster stations that automatically mix the mortar and apply it under pressure to the surface to be treated.

2. Advantages of mechanized plaster

Mechanized plaster has a number of significant advantages over the manual method:

- Speed of operation: Thanks to the use of machines, the process of applying plaster is accelerated several times. This is especially important at large facilities, where the speed of work execution plays a key role.

- Coverage quality: Mechanized application allows for a more uniform and smooth coating without visible transitions and irregularities, which significantly improves the appearance of the walls.

- Saving materials: Machines allow more precise dosing of the solution, which reduces its consumption and, consequently, the cost of materials.

- Reduced labor costs: The use of machines reduces the physical strain on workers, which increases their productivity and reduces the likelihood of errors and defects.

- Versatility: Mechanized plaster is suitable for processing various types of surfaces – brick, concrete, foam concrete and others.

3. Equipment for mechanized plastering

Special machines – plastering stations-are used to perform mechanized plastering. They come in various types, but the basic design elements are similar:

- Dry mix bin: It is filled with dry plaster mixture, which is then fed into the mixing chamber.

- Mixing chamber: In this unit, the dry mix is mixed with water until a homogeneous plaster solution is formed.

- Pump: Serves to supply the finished solution under pressure through a hose to the sprayer.

- Spray Gun: A device for applying mortar evenly to the wall surface.

- Management system: Includes panels and remotes with which the operator controls the operation of the station and adjusts the parameters of applying the solution.

4. The process of performing mechanized plastering

The process of mechanized plastering includes several stages::

- Surface preparation: The wall surface is cleaned of dust, dirt, old plaster and other contaminants. If necessary, primers and adhesive compounds are applied.

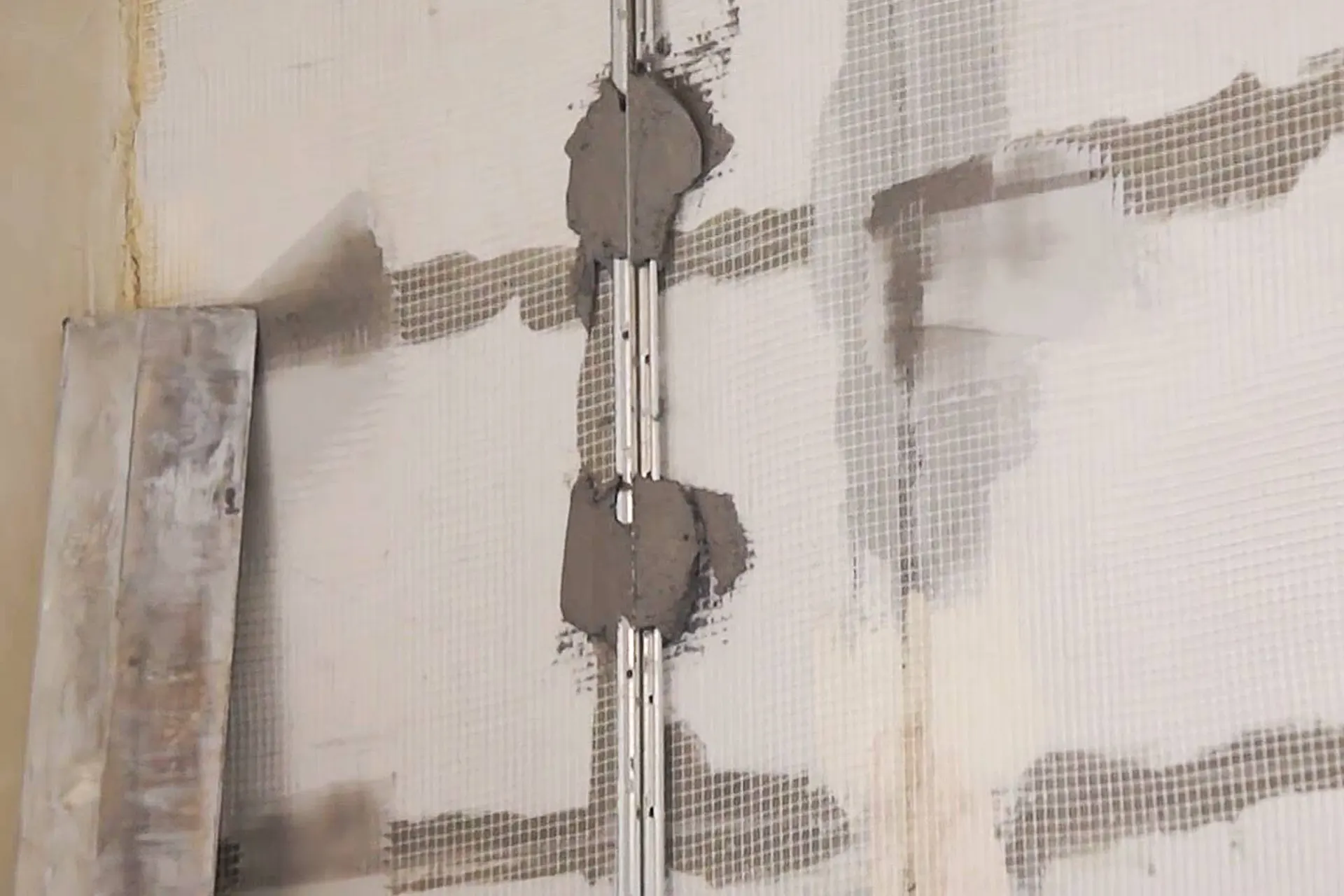

- Installing beacons: To ensure the smoothness of the plaster layer, beacons are installed on the wall – special guide profiles that set the level of the future coating.

- Preparation of the solution: The station hopper is filled with dry mix, which is mixed with water until a homogeneous solution is obtained.

- Applying the solution: The finished solution is fed through a hose to the sprayer and applied evenly to the wall. The operator adjusts the layer thickness and controls the application process.

- Layer Alignment: After applying the mortar, the surface is leveled using rules and spatulas to ensure smoothness and even surface finish.

- Grout: After the plaster has dried, the surface is additionally rubbed to remove small irregularities and obtain a perfect smoothness.

5. Types of plastering machines

Plastering machines come in various types, depending on the method of feeding and applying the mortar:

- Pneumatic machines: Use compressed air to feed the solution through a spray gun. They are characterized by high productivity and are used for processing large areas.

- Hydraulic machines: The solution is supplied by a hydraulic pump. These machines are less noisy and can be used indoors.

- Electric machines: Powered by an electric motor and suitable for use in facilities with access to electricity.

- Mechanical machines: Use mechanical drives to supply the solution. They are used in conditions of limited access to electricity and compressed air.

6. Selection of materials for mechanized plaster

When choosing materials for mechanized plaster, it is necessary to take into account the type of surface, operating conditions and requirements for the final coating. The main types of plaster mixes are:

- Cement mixes: Suitable for outdoor and high humidity applications. They have high strength and water resistance.

- Gypsum mixes: Suitable for indoor use in dry areas. They are characterized by good ductility and high drying rate.

- Polymer mixtures: They have improved adhesion properties and can be applied to various types of surfaces, including complex and smooth ones.

7. Features and recommendations for working with mechanized plaster

When working with mechanized plaster, it is necessary to take into account a number of features and follow certain recommendations:

- Maintaining equipment cleanliness: After the machine is finished, it must be thoroughly cleaned of any remaining mortar to avoid clogging and damage to the machinery.

- Mixture quality control: The dry mix must be homogeneous and free of lumps. The water used to prepare the mortar must be clean and meet the requirements of building codes.

- Correct application: The mortar should be applied evenly, avoiding gaps and congestion in individual sections of the wall. The optimal layer thickness is determined by the type of mixture and operating conditions.

- Compliance with safety regulations: When working with the machine, it is necessary to use protective equipment-glasses, gloves, hard hats. Electrical and hydraulic machines must be operated in accordance with the manufacturer's instructions.

Conclusion

Механизированная штукатурка стен в Димитровграде – это современная технология, которая значительно упрощает и ускоряет процесс отделки помещений, улучшает качество покрытия и снижает затраты на материалы и труд. Использование штукатурных машин позволяет добиться высокого уровня автоматизации работ, что особенно важно на крупных строительных объектах и при выполнении отделочных работ в сжатые сроки. Соблюдение рекомендаций и правил эксплуатации оборудования гарантирует долговечность и эстетическую привлекательность готовых поверхностей.